cable blowing machines

Posts

Cable Blowing Machines

/2 Comments/in Fiber optic cable blowing machines/by adminCable blowing machinines, The technique is simple for those who know what needs to be done; otherwise the whole business gets pretty complicated. The cable blowing machines, thus should be chosen with through understanding the need and the final purpose of the same. The machines are provided by manufactures to suit various different needs of the users. The design of each machine is unique and the owners know their use best.

If you are in dire need of a fiber optic cable then you will need a fibre blowing machines that will provide the required cable and the diameter, the length and the strength to ensure high performance. The market is flooded with the machines that allow the insertion of opticalfiber in the cable. Each such process is unique and each such process calls for expertise.

The methods that are used by the fiber optic cable blowing machines mainly depend on the diameter of the cable that needs to be produced. If the need is for less diameter then micro duct machine will be used which will allow the insertion of the optic fibre in smaller air compressed zones.

Machine soufflage portage fibre

The way is liked over the other forms as the air compressed and blowing method allows the wire to reach long ends and this can create a strength that otherwise is difficult to achieve. The manufacturers mainly depend on this technology as it is reliable and allows flexibility. The users have been quite specific in their demands those can only be achieved by use of independent technology which knows how to fulfill the purpose.

Using of optical fiber has seen an increase over the years. The fiber allows the flow of waves in seconds which is the prime reason why so industry uses are dependent on the fiber cables. Here an important thing to note is that each such type of use calls for a particular type of cable production. This generally means that the variation is in the type of cable diameter, strength, etc. Here the cable blowing machines is used for the purpose of creation of a suitable cable length and diameter.

The machines that are used are designed in unique ways. There are large numbers of such patterns in the machine that are thus capable of creating a suitable outcome. The cable blowing machines is used by various such manufacturers over certain other options as these are something that uses the latest technology and are highly reliable as an outcome.

The process of cable blowing machines is not complicated and has been in practice for long. The whole system is based on the concept of pushing something in by creating enough space area which without the required space may be a problem due to friction. The machines that are used to insert the fiber optics use compressed air to make their process easy and reliable. The outcome is larger cable lengths and more durability due to expertise and performance. If not for this then a lot of power was being wasted in creating the fiber cables according to ones needs.

Machine de soufflage fibre optique prix.

Microduct fiber blowing machines

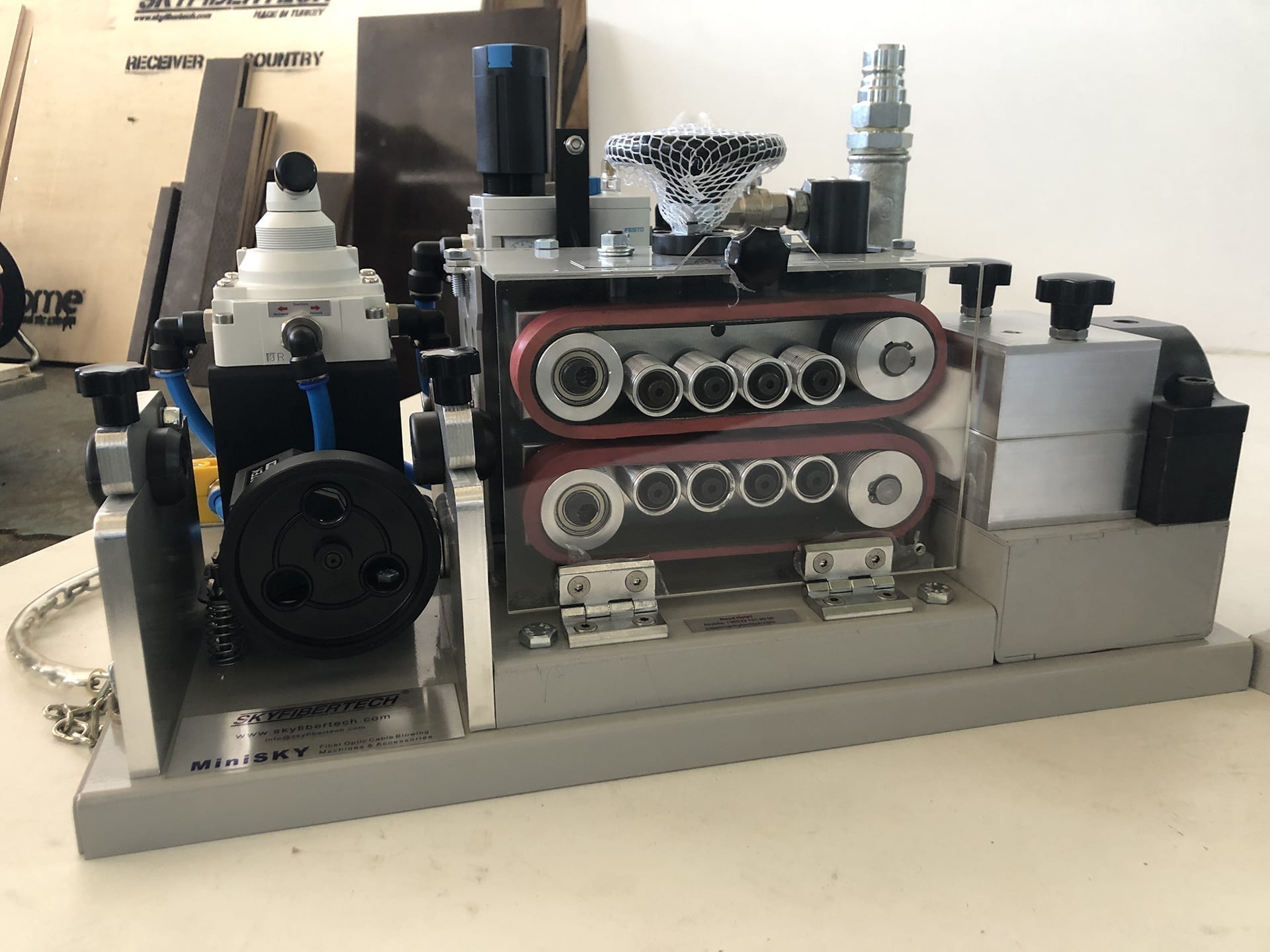

/0 Comments/in Fiber optic cable blowing machines/by adminMicroduct fiber blowing machines

Whether it’s a small building or wide area where the fiber optic cable connection has to be installed it needs special care and attention. The reason why fiber optics is handled very carefully is the different formation of cable and the unique technology based on what the cable works. According to the modern science this is the most efficient cable that’s ever been used to transfer data at light speed. The speed of data transfer depends on the fiber quality and material used and also on other factors. ANSI and other organization also give strict direction which every agency has to follow while manufacturing and installing fiber optic cables via microduct fiber blowing machines.

There are many small tools and machines are used to establish the connection under the surface. The pulling rate of fiber cable through the duct should be 3 feet per second in case of rope. There are many other safety measures applied in the fiber optics installation process as the cable is quite expensive and once it get damaged the whole install process have to be altered. The UV radiation and other safety precaution needed to take while making an installation.

The inspection process of live fiber is very important and dangerous too. It needs special glasses to wear by the technician to prevent retina damage. Inspection of both the end should be done by Microduct fiber blowing machines not manually to avoid risk. The machines like microduct fiber blowing machines, battery etc are the main machines and tools which are used to establish a fiber optic cable connection.

Fiber Blowing Machines

To install fiber optic cable there are many arrangement needs to be made as it is quite sensitive type of cable used for high capacity data transfer. Microduct fiber blowing machines is one of the necessary expensive machine that is being used to make the installation easier. While establishing a fiber optic connection within a perimeter this machine shows an outstanding efficiency. The level of manual laborbecomes rapidly less by using a blowing machine which works on the compressor with heavy air pressure and establish a network under the surface very cost effectively.

There are many other machines like microduct fiber blowing machines also used to push the fiber cable between the HDPE ducts which keep the cable safe from external hazards. Talking of fiber optic cable you have to be extra careful while using this machine and this special cable which works on the optical fiber signal. Basically, ina manual network installation, there are several risks and extra costs involved that is the reason the jetting machine and blowing machine comes into the picture to make the work super flexible with less human effort.

There are many features of microduct fiber blowing machines which is especially built to handle large and small network by using fiber optic cable. The operator just needs to know the controls and step by step procedure to start and stop the machine and the rest of the blowing of cable through the duct will be done by this machine and definitely in less time.

How to handle fiber optic cables

/0 Comments/in Fiber optic cable blowing machines/by adminHow to handle fiber optic cables

Dealing with fiber optic installation is not a very easy task. While installing fiber cable there are two sections of work that engineers do. One is known as general section and the other one is known as cable installation. Fibre optic cables installation has to be done by following the international standards of safety measures and the cable handling need paying attention on the manufacturer’s instruction about the fiber cable. The main purpose should be the proper installation so that the fiber optic cables get the maximum support when it will be buried to make long distance connections.

Most of the high speed data transfer connections are made by fiber optic cables. Initially a fiber optic cables may look like normal cables, but under the plastic coating there are many thin layers of colored fiber wires designed to transfer data at a lightning speed. There are many varieties of these cables are used in the telecom industry depending upon the desired speed of data or level of data to be transferred simultaneously. While installing a fiber optic connection into a locality the engineers and the worker has to careful enough while pulling the cables from one end to another as it is highly sensitive.

Fiber optic cables always needs expert’s care. The formation is quite complex than normal cables. Jerking the cable, pulling with high tension can alter the inner setting and as a result the performance may hamper or the whole cable can get wasted which may increase the installation cost.

More informaiton please visit fiber optic cables.

Cable Jetting

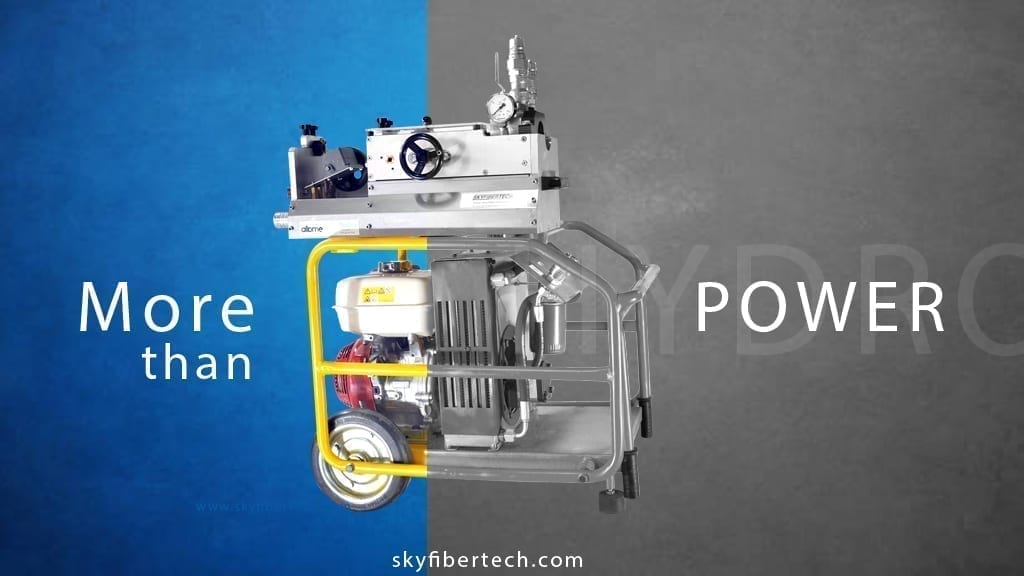

/4 Comments/in Fiber optic cable blowing machines/by adminCable blowing machines or Cable Jetting Machines are very usefull to long distance process. Buy one machine save your time and money. More information please contact us.

A Few Important Features Of Cable Jetting

The device named cable-blowing machine has been an extremely important machine. It is a device that is specially designed to fit the fibre optic cables namely to the telecommunication ducts with the assistance of either air or water.

Cable Jetting

General features of the device:

Now let’s have a view on the general features of the device.

There is an air compressor that is specifically designed for use of the micro fibre cable jetting. This is a very reliable and trusted screw compressor, which is powered by gasoline engine. It provides maximum work pressure of 220psi with about 35.3 cms. The compressor is also modified in a special way to include an after cooler and water separator specifically. The output air is then filtered and conditioned for better performance of the machine. The compressor package generally includes a 50-foot diameter air hose for connection to the machine.

The new cable jetting machine has been classified according to their compression ratios. It will be quite interesting to know that blowing machines are also sometimes termed as blast blowers or draft blowers mainly in iron and steel industries. They are most frequently used in such industries.

This type of machines is mainly used in many industries. They reduce the load of work to a great extent. It can be said that the introduction of new machines has reduced work mainly manual one to a large extent. This is all possible only due to the invention of latest technologies. Man is much more dependent on this machine as they have reduced working manner. It has been estimated that day-by-day the use of this machines will increase further instead of reduction. It is hoped that in future there will be more such machines to reduce load.

Cable Jetting Machine