Process of working of fibre blowing machines!

Cable-blowing-machine

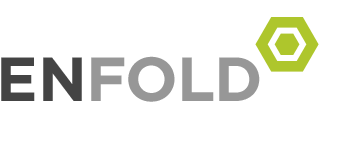

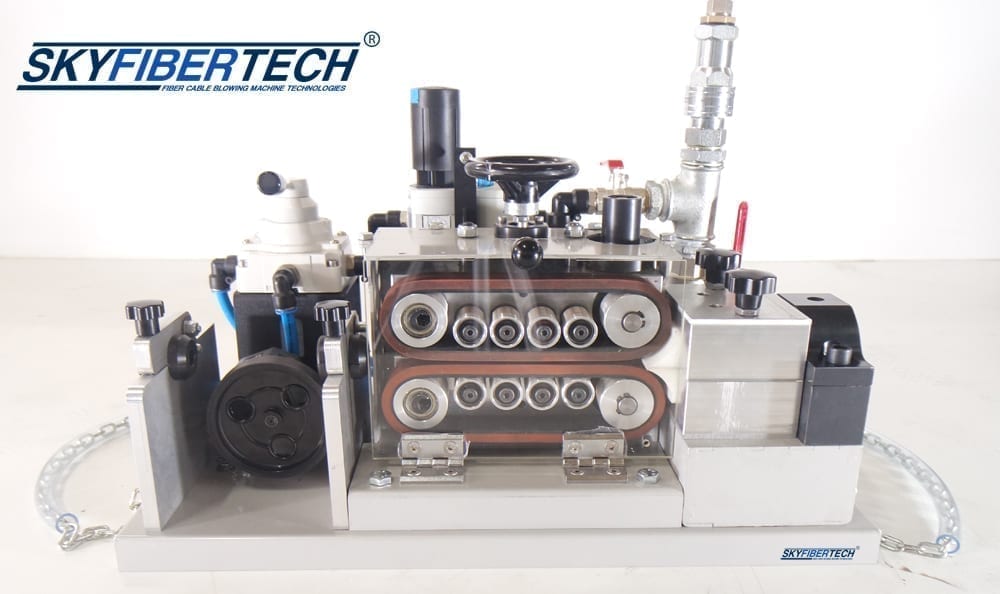

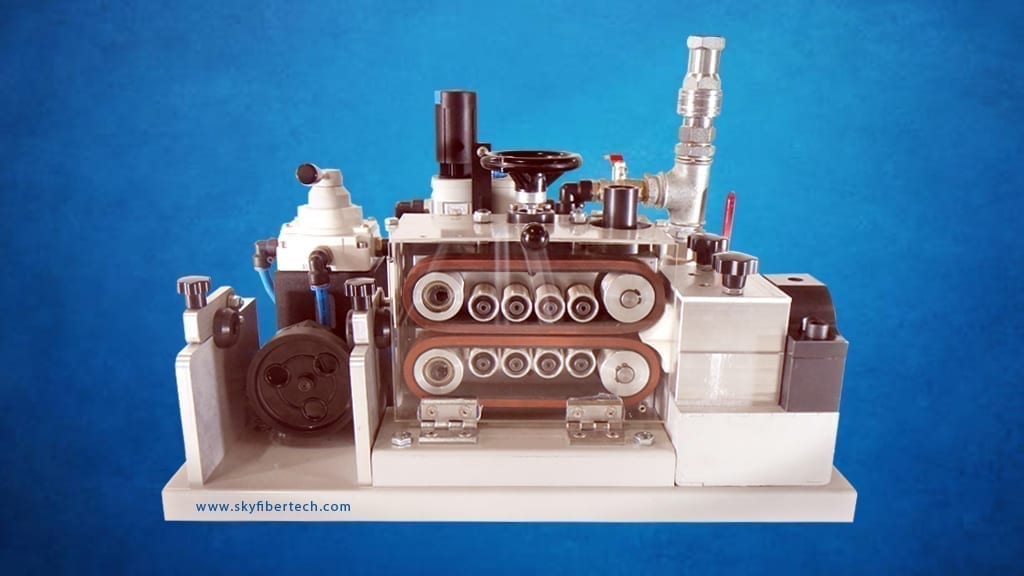

The process of fibre blowing machines while establishing a network is not very complex when you are using fibre blowing machines. This machine is the ultimate and the latest technology used for telecommunication installation purposes. The operators who handle the machine have to have enough knowledge of using several stages of using the blowing machine. The machine works on the fuel engine which constantly supply the power to the hydraulic system. There are several valves involved in controlling the fuel into the blower. The control shaft controls the speed of air pressure and let the fiber optic pass through the duct.

- This powerful machine lets you complete installation of fiber optic cable in a network very efficiently.

- You can use this machine to make a flexible connection in a complex networking area.

- The fibre blowing machines prices is a little higher, but as return you can complete the whole networking very easily with less manual labor and cost.

- You can also move this hydraulic air blowing machine from one place to another very easily as it is assembled on four wheels.

The process of operating the fibre blowing machines is very comfortable with less effort. The machine has the inbuilt generator which needs to be turned on before placing the cable into the blowing machine. fibre blowing machines has the functionality which can be controlled manually. You can measure the air pressure reading on the meter and control the air pressure depending on the need of installation.