Advantages of fiber cable blowers

Fiber optic cable blowers!

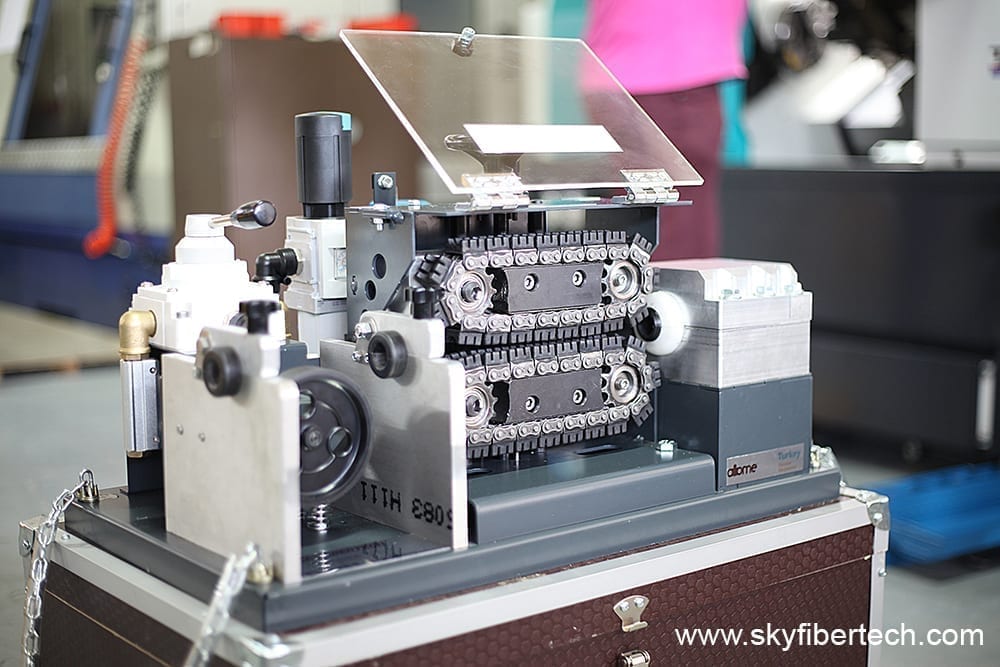

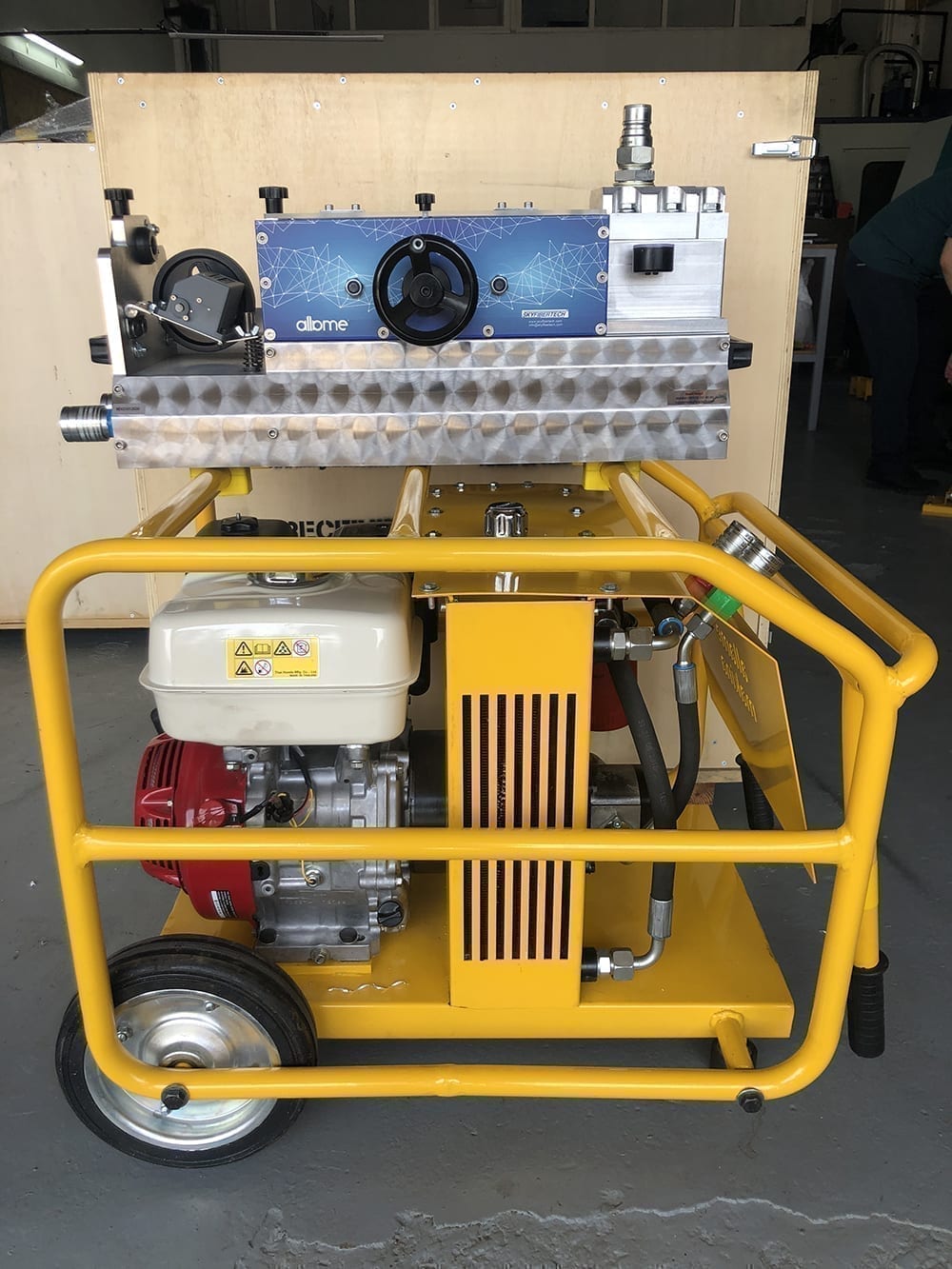

There are a large number of advantages because of which the fiber optic cable blowing machine is used over other methods or inserting the fiber cable in the ducts. The industry is a growing one, there is constant demand for cable with specifications and features different from one another. This is as these cables are used for various different purposes and thus even the blowing machines are categorized by the purpose they solve. On this base there are two categories- one which comprise of machines that produces cables that have 10mm diameter and more and then there are machines that are used for micro duct and produces cables which are 10mm below.

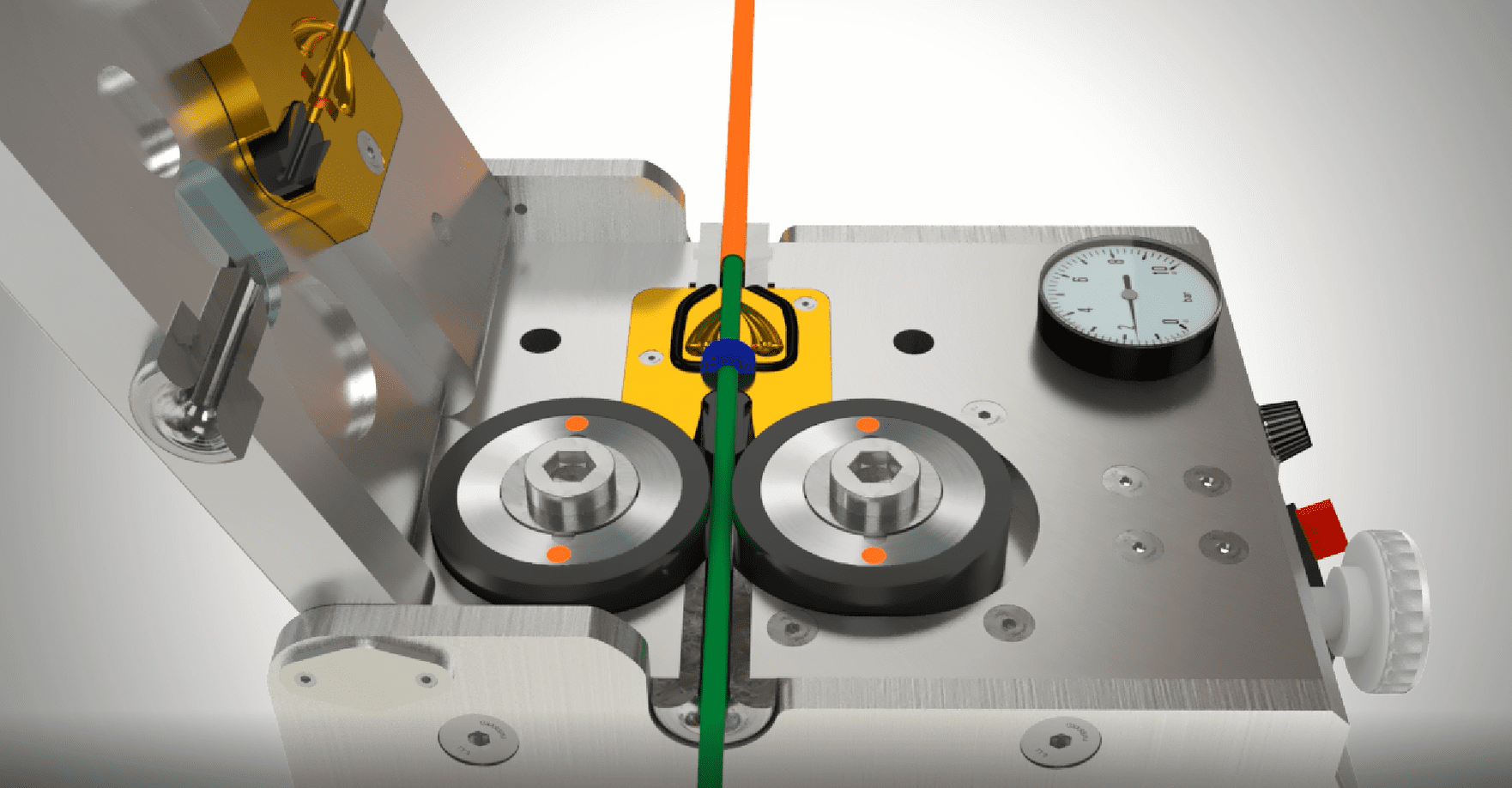

The whole process of the cable blowers is somewhat similar no matter what the cables are being produced. The process involves the insertion of cables with the help of compressed air which makes way for the fiber optic cable blowing machines to move through quickly and along with that the exerted pressure that ensures that the process is continuous and timely. This also ensures less wear and tear and even lesser damages to the wire being inserted. That is why more and more people are shifting to using this technology over others.

The use of fiber optic cable blowing machine is not uncommon and it has increased over the years due to the various advantages that it offers. The best amongst them is the production of longer cables with the use of the mechanical process. Since there is no delay the process the resultant economic benefits are also many.

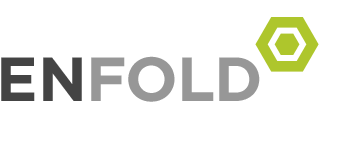

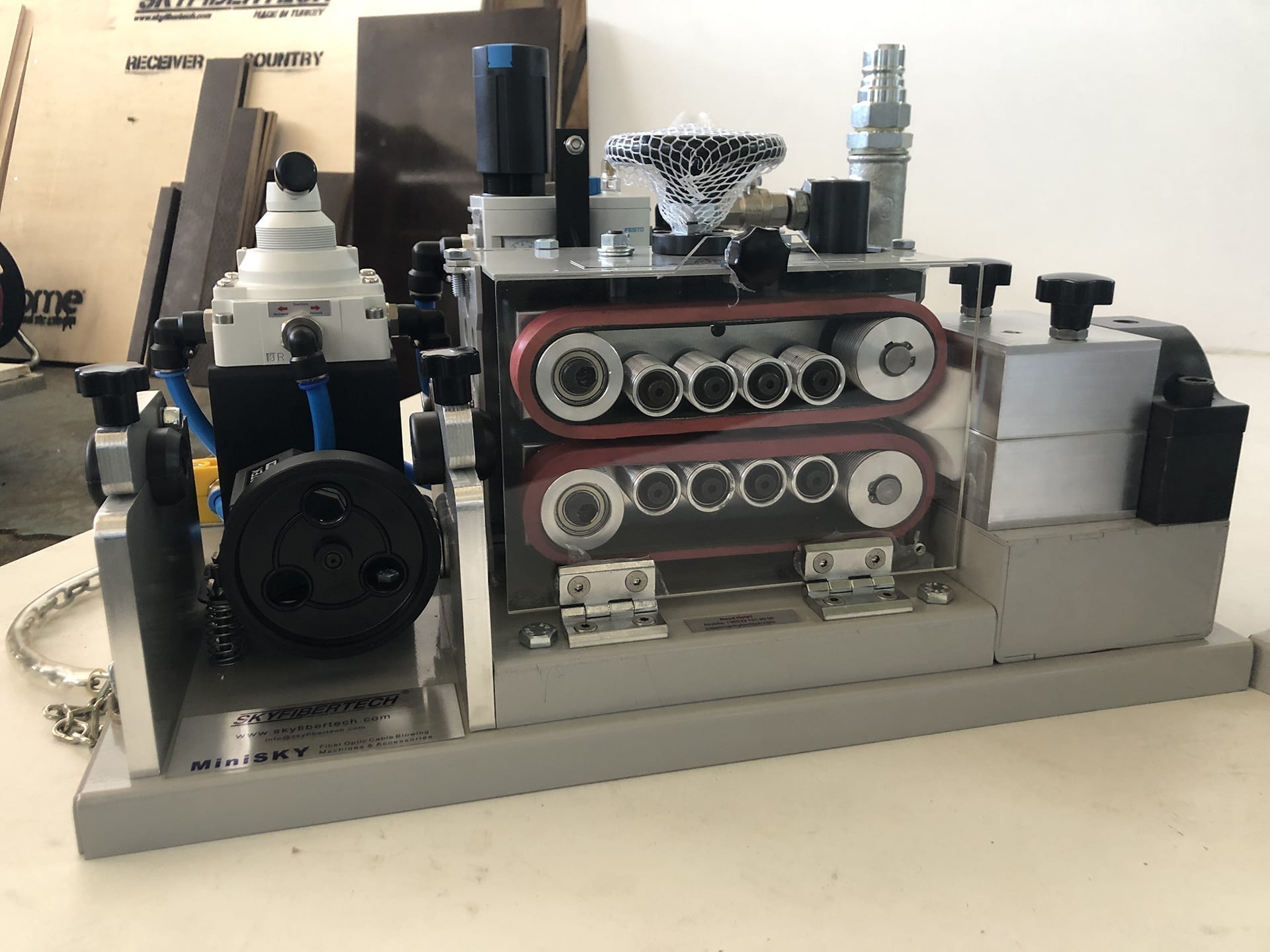

cable blowers MiniSKY

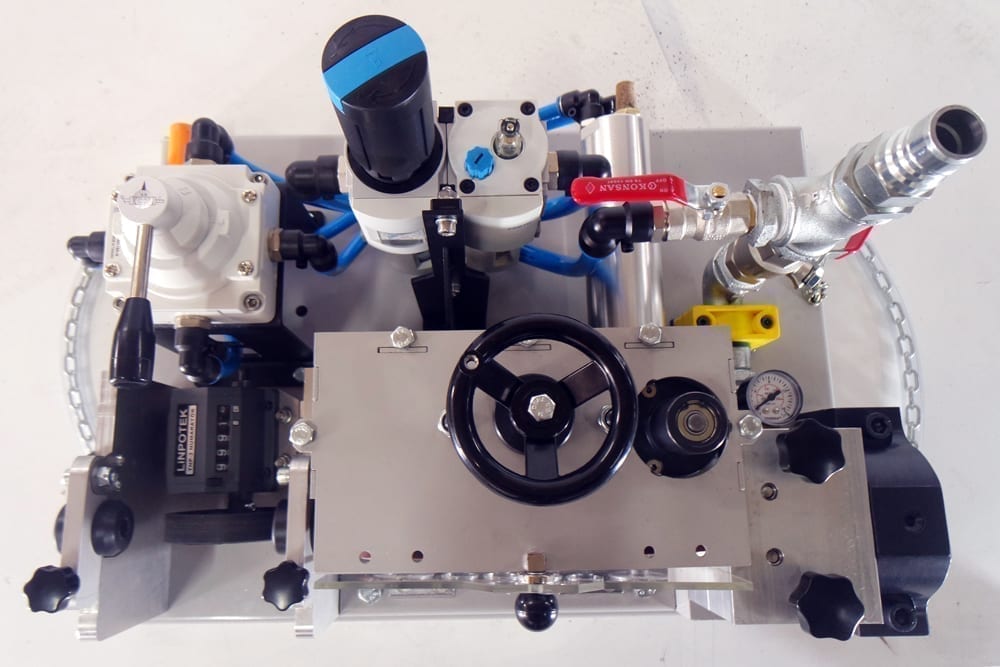

- Operating fiber optic blowing machine

When you work on a critical telecommunication network installation fiber optic cable handling is one of the essential parts of it. By using Fibre optic cable blowing machine the work of networking become much easier. Before manual labor level was very high for this kind of work, but since this type of machines came into action long distance fiber optic connection can also be done with less time and efficient cost factor. Smart use of blowing machine and other supporting tools makes the networking or cabling work very easier, whether it’s a small building or long distance underground fiber optic connection.

The concept of blowing machine and jetting machine is totally based on the latest hydraulic system which means less human labor and less cost. The air blowing technology is used to establish the fiber optic cable connection through the duct. The range of fiber optic cable from 1 mm to 30 mm can be blown through Fibre optic cable blowing machine that means through this single machine you can do most of the networking very easily. The simple controlling process of the air compressor can be increased or decreased according to the need.

Along with the blowing machine, there are other several machines and small tools also needed to install a fiber optic connection successfully. Fiber Optic Cable Jetting Machines are another expensive machine which decreases the manual labor in fiber optic networking. These machines are the advance technology which is being used almost every telecom service agency in every country.